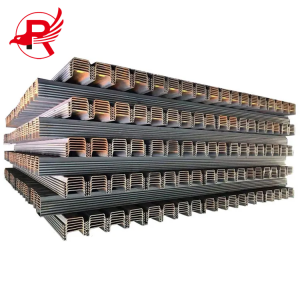

Firotanên Germ Hemû Cureyên Pîlên Pola yên Germkirî Pîlên Pola yên UZ Tîpa 2 Tîpa 4

| Navê Berhemê | Pîlên pola yên germ-gêrkirî yên celebê U/Z ji bo avakirinê | |||

| Materyal | Q235, Q345, Q390 | |||

| Teknîk | Germkirî, sar şekildayî | |||

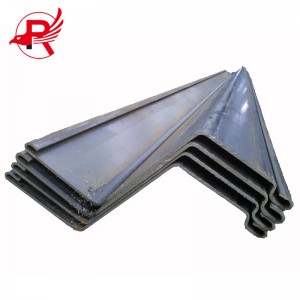

| Awa | Cureyê U /Z | |||

| Şehade | ISO | |||

| Dirêjî | Her dirêjahî wekî daxwaza xerîdar | |||

| Cihê jêderkê | Çîna sereke | |||

| Pakêt | Bi girseyî, pakkirina deryayî an jî li gorî daxwaza xerîdar bikirin | |||

| Bikaranînî | projeya lehiyê, projeya avakirinê, pir û hwd. | |||

| Dema dayinê | TT | |||

| Bixçe | Keşti an konteynirek girseyî | |||

| Şandinî | TT | |||

pileya pelên Z yên sar-çêkirîdi endezyariya sivîl û avakirinê de xwedî rêzek fireh a sepanên wan in. Hin ji sepanên wan ên sereke ev in:

- Dîwarên Ragirtinê:Pola Z ya Germkirîbi gelemperî ji bo çêkirina dîwarên ragirtinê di projeyên avakirinê de têne bikar anîn. Ew dikarin ax, av, an materyalên din biparêzin, û ji bo kolandinan an jî şemitokan aramiyê peyda bikin. Dîwarên pola yên ji pelên pola pir caran di parkgehên bin erdê, avakirina jêrzemînan û avahiyên beravê de têne bikar anîn.

- Bendavên Qefesê: Di çêkirina deryayî û piran de,pileya pelên cureyê UPîl ji bo çêkirina bendavên sifonê tên bikaranîn. Bendav avahiyên demkî ne ku ji bo dûrxistina avê ji qada avakirinê tên çêkirin, û dihêlin ku karê avakirinê di hawîrdorek hişk de were kirin. Pîlên pelê pola di erdê de tên çikandin da ku li dora qada avakirinê astengiyeke avnegir çêbikin.

- Parastina ji Lehiyê: Pîlên pola di projeyên parastina ji lehiyê de ji bo avakirina dîwarên parastina ji lehiyê têne bikar anîn. Ev dîwar dibin alîkar ku pêşî li ketina ava lehiyê bo deverên niştecihbûyî an jî deverên hesas di dema barana giran de an jî li deverên peravê yên ku meyla wan bi pêlên bahozê heye, bigirin.

- Avahiyên Qeraxê Avê: Pîlên pola bi gelemperî di avakirina avahiyên qeraxê avî yên wekî dok, dîwarên keştî, îskelet û termînalên deryayî de têne bikar anîn. Ew îstîqrar û berxwedana li hember zexta avê peyda dikin, û rê didin lengerkirina ewle ya keştiyan û desteserkirina barhilgiran.

- Kolandinên Demkî:Pîleya Zçareseriyeke îdeal in ji bo kolandinên demkî yên wekî xendek û çalan. Ew dikarin bi hêsanî werin sazkirin û rakirin, û rêbazeke bilez û bibandor ji bo afirandina cihên kar ên demkî ji bo xizmetguzariyan, sazkirinên boriyan û projeyên avakirinê peyda dikin.

- Avahiyên Bin Erdê: Pîlên pola di avakirina avahiyên bin erdê yên wekî jêrzemîn, parkkirina bin erdê û tunelên bin erdê de jî têne bikar anîn. Ew piştgiriya avahîsaziyê peyda dikin û dibin alîkar ku pêşî li tevgera erdê an ketina avê nav avahiyan bigirin.

Not:

1.Belaşnimûnegirtin,%100Dabînkirina kalîteya piştî firotanê, Piştgirîher rêbaza dravdanê;

2. Hemû taybetmendiyên din ênlûleyên pola karbonê yên dorli gorî hewcedariya we peyda dibin (OEM û ODM)! Bihayê kargehê ku hûn ê ji wê bistîninGRÛPA ŞAHANÎ.

Pêvajoya hilberînapîlê pelê pola yê cureya zbi gelemperî gavên jêrîn pêk tîne:

1. Amadekirina Materyalan: Materyalê xav ji bo stûnên pelên pola bi gelemperî bobînên pola yên germ-pêçayî ne. Kalîteya van bobînan bi baldarî tê kontrol kirin û dûv re têxin xeta hilberînê.

2. Birîn û Qutkirin: Pêlên pola pêşî heta firehiya pêwîst têne birîn û dû re dibin pelên ferdî. Ev pêvajo piştrast dike ku pelên pola ji bo serlêdana taybetî bi mezinahî û şeklê xwestî ne.

3. Şêwekirin: Pelên pola yên qulkirî dû re têne şandin nav aşê gerandinê an makîneya şêwandinê, li wir ew li gorî profîla xwestî têne şêwandin. Makîneya şêwandinê rêze rolên xwarbûnê an jî presên hîdrolîk bikar tîne da ku pelên pola bi şiklê pêwîst, wek şiklê U an şiklê Z, şêw bike.

4. Girêdan û Qefilandin: Ji bo çêkirina dîwarekî an astengiyeke domdar, pêdivî ye ku stûnên pelan ên ferdî bi hev ve werin girêdan û girêdan. Ev bi rêbazên cûrbecûr ên wekî xendekên girêdayî, girêdanên qelandî, an jî bi karanîna girêdan an jî kelemçeyan tê bidestxistin. Mekanîzmaya kilîtkirinê piştrast dike ku stûnên pelan bi hişkî ve girêdayî dimînin û hêz û aramiya pêwîst peyda dikin.

5. Birrîn li gorî Dirêjahîyê: Dema ku stûnên pelan ên bi hev ve girêdayî têne çêkirin, ew li gorî dirêjahiya xwestî têne birîn. Ev gav piştrast dike ku stûnên pelan ji bo projeya avakirinê ya taybetî bi dirêjahiya pêwîst in.

6. Dermankirina Rûyê: Li gorî sepandin û hewcedariyan, dibe ku stûnên pelên pola pêvajoyên dermankirina rûyî derbas bikin. Ev dikare pêvajoyên wekî teqandina guleyan, galvanîzekirin, an boyaxkirinê di nav xwe de bigire da ku berxwedana li hember korozyonê baştir bike û xuyangê estetîkî baştir bike.

7. Kontrola Kalîteyê: Di tevahiya pêvajoya hilberînê de, tedbîrên kontrolkirina kalîteyê yên hişk têne bicîh kirin da ku rastbûna pîvanan, taybetmendiyên mekanîkî û kalîteya giştî ya stûnên pelên pola werin misoger kirin. Ev dibe ku ceribandinên wekî ceribandina kişandinê, ceribandina xwarbûnê û vekolîna dîtbarî di nav xwe de bigire.

8. Pakkirin û Radestkirin: Pileyên pelên pola yên qedandî dû re bi rêkûpêk têne pakkirin, bi gelemperî di nav komekan de, û ji bo veguhastinê bo şantiyeya avakirinê an tesîsa depoyê têne amadekirin. Di dema veguhastinê de bal tê kişandin ku pileyên pelan werin parastin da ku zirarê nebînin.

Pakkirin ebi gelemperî tazî, girêdana têla pola, pirqewî.

Heke hewcedariyên we yên taybetî hebin, hûn dikarin bikar bîninpakkirina dijî zengarê, û xweşiktir.

Neqlîye:Veguhestina Ekspres (Radestkirina Nimûneyan), Hewayî, Rêhesinî, Bejayî, Deryayî (FCL an LCL an jî Barkêş)

Xerîdarê kêfxweş

Em ji xerîdarên li çaraliyê cîhanê ajanên Çînî werdigirin da ku serdana pargîdaniya me bikin, her xerîdar bi bawerî û pêbaweriya xwe di pargîdaniya me de tije ye.

Q: Ma hûn hilberîner in?

A: Belê, em hilberîner in. Kargeha me li bajarê Tianjin, Çînê ye.

Q: Ma ez dikarim fermanek ceribandinê tenê çend ton bistînim?

A: Bê guman. Em dikarin bar ji bo we bi karûbarê LCL bişînin. (Kêmtir barkirina konteynerê)

Q: Ger nimûne belaş be?

A: Nimûne belaş e, lê kirrûkar ji bo bargiraniyê dide.

Q: Ma hûn dabînkerê zêr in û piştrastkirina bazirganiyê dikin?

A: Em heft sal dabînkerê zêr in û piştrastiya bazirganiyê qebûl dikin.